Merritt Herald Article about Nicola LogWorks

The Timber Times

October 2nd 2020

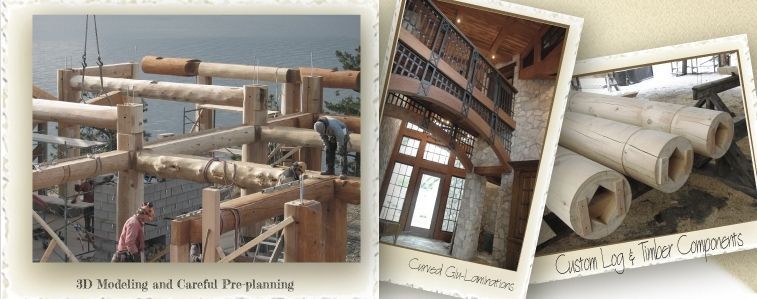

Nicola LogWorks refines craftmanship with technology

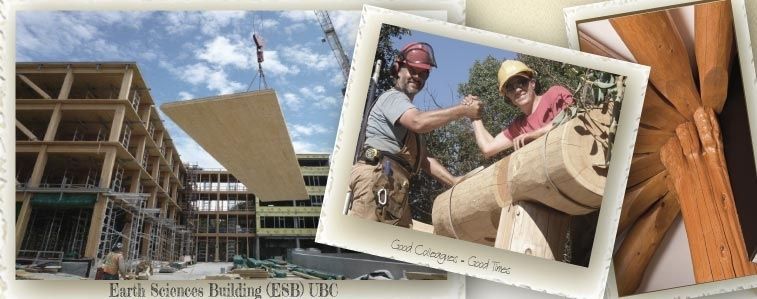

The Nicola LogWorks crew is shown with their log-building robot, named ABBy, who helps them refine their craftmanship in the most minute of details.

The log cabins of old were born of necessity. A settler in a remote corner of the Canadian wilds often faced the prospect of dying of exposure over the course of a harsh winter without shelter.

These traditional log cabins could be assembled with nothing more than the readily available timber, rudimentary tools, backbreaking labour and the sweat of your brow. If you were lucky it would be mostly weatherproof, and maybe even include windows and a woodstove.

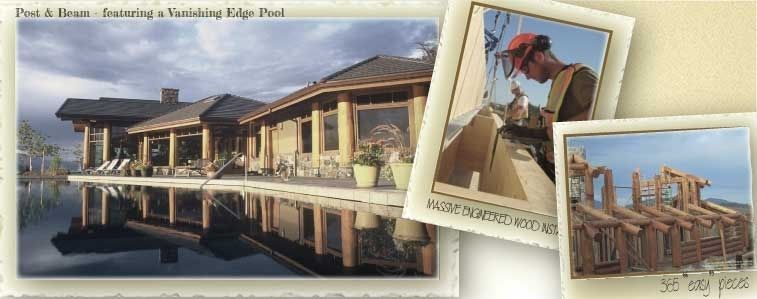

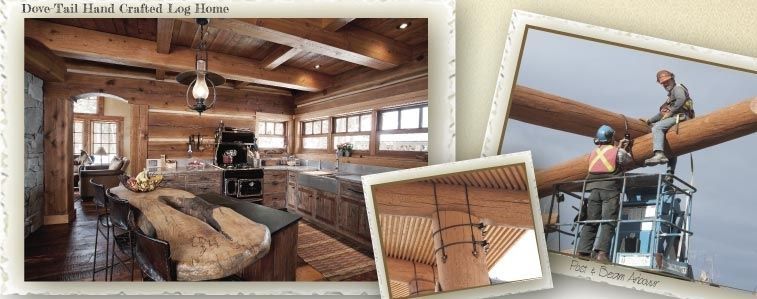

Today, log homes have evolved to be a testament to fine craftsmanship. Combining beauty with function and becoming increasingly high-tech, while still retaining the elements of style and the romance of history and humble beginnings.

John Boys, owner of Nicola LogWorks, has been building log homes for more than 30 years, and has operated Nicola LogWorks since 1993.

“I discovered a passion for log building when I took a two week course at the B. Allan Mackie School of Log Building as a way to fill time between jobs on the oil rigs, after which I became an itinerant log builder; working with and being mentored by, some of the best log home builders in BC and Alberta,” said Boys.

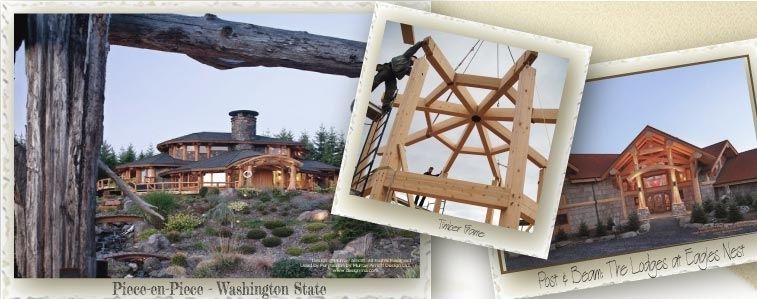

A Robot Assisted/'Hand-Crafted Log Piece-en-Piece Home is loaded at Nicola LogWorks in Merritt BC; Destination - Up State New York

“It was during this time that I met and worked with Brad Hagen, who went on to set up Harvest Log Homes in Merritt, BC.”

In 1989, Boys came to Merritt in order to help Hagen meet a production deadline, his single-job plan turned into a loose partnership with Hagen and he has been building in the Nicola Valley ever since, remaining even after Hagen left for Germany to help launch a log building business there.

“Merritt is an ideal location for the business,” explained Boys.

“Minimal precipitation and the arid climate make log storage and air drying of wood fibre viable, and our proximity to transportation routes is also an advantage.”

Log homes, which had fallen out of popularity for a time, had once again become a desirable form of dwelling.

“In the 1980s, the early years of the ‘log building revival’, most of the BC log builders were exporting to a booming market in Japan, and Nicola LogWorks was no exception,” said Boys.

However, in addition to being a hands on type, Boys had also earned a degree in economics. By the mid-nineties he decided to expand his business outside of the Japanese market, fearing an eventual crash that could spell disaster if he had “all of his eggs in one basket”.

The quality craftsmanship of Nicola LogWorks helped Boys to establish a solid foundation in the US, Scandinavia and Europe, a foundation upon which many log homes have since been built. Although the financial crisis of 2007 lead to a decline in foreign markets, a renewed desire and demand for log homes began in Canada.

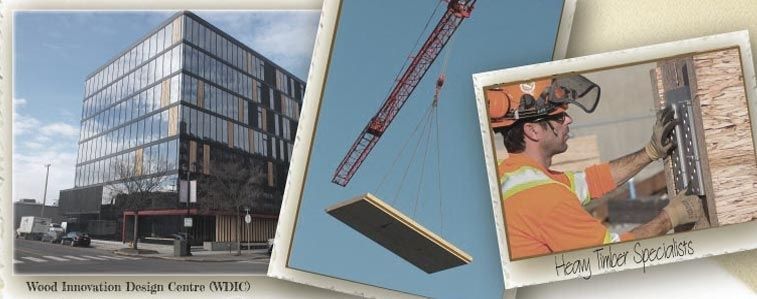

“In light of the ‘Wood First’ initiative, a mandate requiring public buildings to incorporate the use of structural wood when possible, we turned our attentions to public projects and commercial structures,” said Boys.

"Hoop Dance" Designed by BrookMcIlroy Architects and cut by Nicola LogWorks uing their custom long and large log lathe

The crew at Nicola LogWorks discovered that their skills could be put to use when the first ‘tall wood structures’ using Cross Laminated Timbers (CLT) were being constructed. Nicola LogWorks was on hand performing pre-planning, rigging, assembly and on-site production of Canada’s first modern tall wood building, the UBC Earth Sciences Building in Vancouver.

Following this the crew installed the mass timber components at the Fort Mac Airport, and in 2013 erected the University of Northern British Columbia (UNBC) Building in Prince George. At 110 feet tall, the UNBC building was briefly the tallest contemporary wood building in the world.

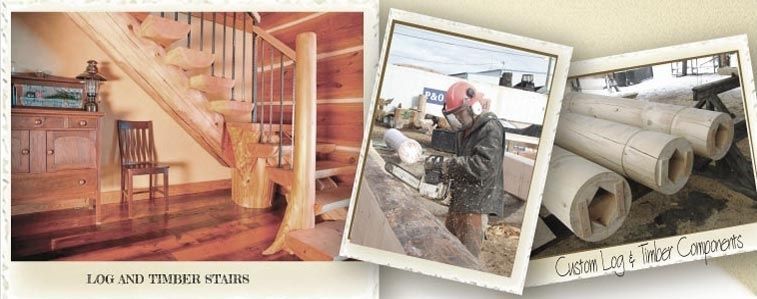

“Some of my favourite projects include three Indigenous Gathering Circles located in Ontario,” said Boys.

These projects were made possible by a piece of equipment called ‘The Machine’, a custom lathe designed by Boys that can handle logs of up to 42” diameter and 57” in length.

Perhaps the most unique and innovative technology to be incorporated into production methods at Nicola LogWorks is a log-building robot, affectionately known as ‘ABBy’, designed by Dusko Ballmer of Ballmer Systems Inc.

Robot-Assisted Log Home. Cut by Nicola LogWorks ahnd crafted team and "ABBy" The Log Building Robot in Merritt BC and delivered to the UK.

“Dusko and I share a dream of producing log homes more efficiently and cost effectively, without losing the organic characteristics of the natural logs or compromising the quality and detail of a well-built hand-crafted log home,” explained Boys.

“Hand-crafted log homes are extremely labour intensive, and obtaining wood fibre that meets the quality and specifications that Nicola LogWorks demands has always been a challenge; ever more so as forestry practices have changed, and short log logging further narrows the candidates that Nicola LogWorks would typically use in their log and timber homes.”

In order to source the ideal wood fibre, Nicola LogWorks works closely with local mill Aspen Planers.

ABBy has not replaced any of the highly skilled craftsmen at Nicola LogWorks, but rather has provided them more time to undertake the dovetail, timber frame, post and beam and scribed building projects, while ABBy is being trained to cut logs for the popular, but expensive, Piece-en-Piece style log homes.

“This is a vintage style of log work that features post and panel construction and is well suited for shorter logs,” said Boys.

“When cut by hand, piece-en-piece is the most expensive type of log work to produce, and while many customers desire it very few have the budget for this style of log work. The piece-en-piece style, however, is ideal for the capabilities of the robot.”

Robotic assisted log building is helping John Boys and Ingrid, his wife, realize a long-held dream of sharing the wellness benefits of natural log and timber in our built environment with a wider range of customers. To date, Nicola LogWorks has delivered four robotic assisted log homes, several sets of spiral stairs cut on the robot and numerous architectural components.

Nicola LogWorks refines craftmanship with technology By Morgan Hampton, Local Journalism Initiative Reporter on September 24, 2020